Dealing with multiple service providers and brands can become a significant risk as response times, quality and inventories vary across suppliers. For crushers, it’s the spare parts that ensure operational uptime; they enable the crusher and the process to keep on going. Wouldn’t it be beneficial to have one premium partner to provide parts and services for all of your crushers? It’s certainly something you should consider with the right partner.

Lower risks with proven know-how

Lower risks with proven know-how

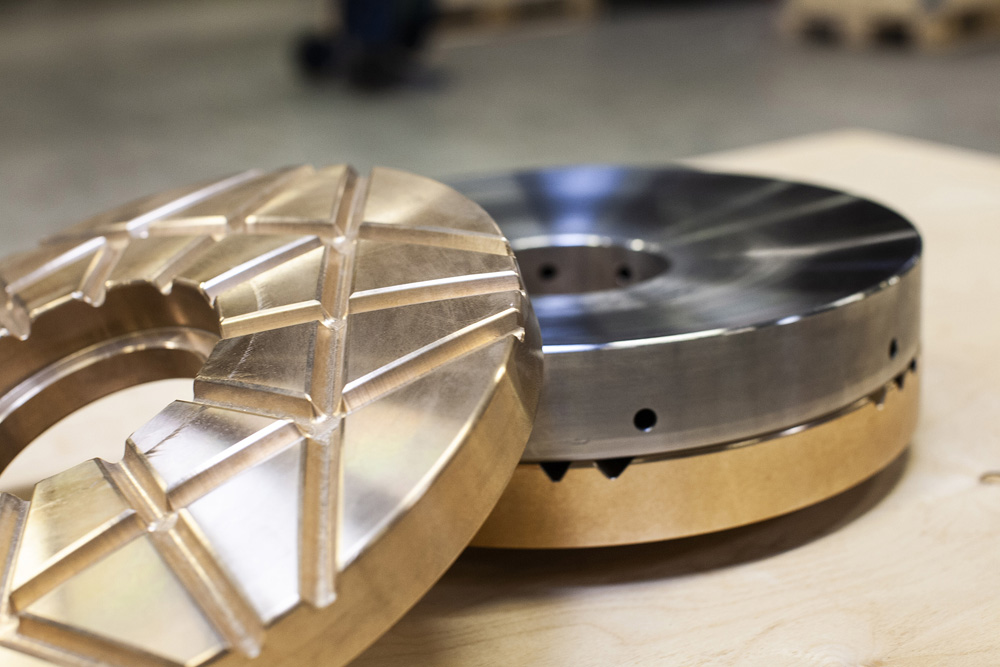

For Metso:Outotec, quality is not limited to a part’s features, but it also means our readiness to provide extended support when needed. Non-OEM part suppliers might have the capability to provide a missing part for the crusher, but is it the right material? The right design? These things can’t be guaranteed, and the risk of malfunction in operation or additional servicing can start to climb if a subpar supplier is used. We’ve combined our legacy as the pioneer of many crusher technologies with our expertise to get a premium series of crusher parts for non-Metso Outotec crushers, the Contender™ Series. These parts are designed to ensure an exact fit and with performance in mind.

Another item to consider is the warranty. If the part doesn’t live up to expectations, you’ll want a strong warranty program in place. With Metso Outotec, an OEM manufacturer, the warranty program lessens the risk of unplanned costs and there is timely follow-up on the performance of your crusher. Our strong footprint and global reach allow for readily available parts whenever you need them.

It is an economical decision to choose a partner, not only a supplier

It is an economical decision to choose a partner, not only a supplier

One of the main advantages of centralizing the maintenance activities of multi-brand crushers, including parts and services, is cost savings. Instead of dealing with multiple interfaces, aggregate producers can have one point of contact to take care of everything. We provide solutions, not just parts and products which makes planning a lot easier and service much more efficient.

Getting ahead of the performance and sustainability game with enhanced crusher parts

While sometimes it might be enough to simply replace a part with the same one, other times there could be opportunities to improve performance. Contender™ Series spares are not limited to standard solutions. We’ve incorporated multiple innovations in the design. In some cases, materials and safety aspects have been improved to enhance the durability and sustainability of the parts. These innovations aren’t accessible from part providers solely focused on replicating the existing ones.

For example, the enhanced spider bushings for non-Metso Outotec crushers are strengthened and have a longer than original operational life to help performance under the toughest operating conditions. Its material has a high residual value when recycled, compared to more traditional materials. Another example is the enhanced dust seal rings, which experience less wear on mating steel parts and less surface contamination from dust and particles due to the self-lubricating design and characteristics of the materials selected. We haven’t limited our expertise to the conventional way of doing things. For example, we have used upgraded metallurgy practices, such as enhanced wood materials in our design for the dust seal rings.

For example, the enhanced spider bushings for non-Metso Outotec crushers are strengthened and have a longer than original operational life to help performance under the toughest operating conditions. Its material has a high residual value when recycled, compared to more traditional materials. Another example is the enhanced dust seal rings, which experience less wear on mating steel parts and less surface contamination from dust and particles due to the self-lubricating design and characteristics of the materials selected. We haven’t limited our expertise to the conventional way of doing things. For example, we have used upgraded metallurgy practices, such as enhanced wood materials in our design for the dust seal rings.

From start to finish, sustainability should be considered in all steps. We use certified beech wood from Europe as the base for our wooden components. Safety is improved by providing part features such as additional lifting lugs and a specialized lifting tool for Metso Outotec-made mantles for third party crushers. Most importantly, your operations become sustainably efficient with one dependable partner.

From start to finish, sustainability should be considered in all steps. We use certified beech wood from Europe as the base for our wooden components. Safety is improved by providing part features such as additional lifting lugs and a specialized lifting tool for Metso Outotec-made mantles for third party crushers. Most importantly, your operations become sustainably efficient with one dependable partner.

Link to Webinar: Managing parts when your site has multiple machine brands Option 1 - Metso

Sponsored content produced in association with Metso Outotec