The Eurasia Tunnel was built to connect the Asian and European sides of Istanbul for the first time via a 3.4km twin-deck road tunnel going underneath the seabed. The 14.6km Eurasia Tunnel route was identified based on extensive feasibility studies conducted in 2005 for the Ministry of Transport, Maritime Affairs and Communications of Turkey. Its main aim was to relieve Istanbul’s transcontinental traffic pressure, reduce travel time and reduce harmful emissions from road traffic.

The project was successfully tendered as a Build-Operate-Transfer project in 2011 to

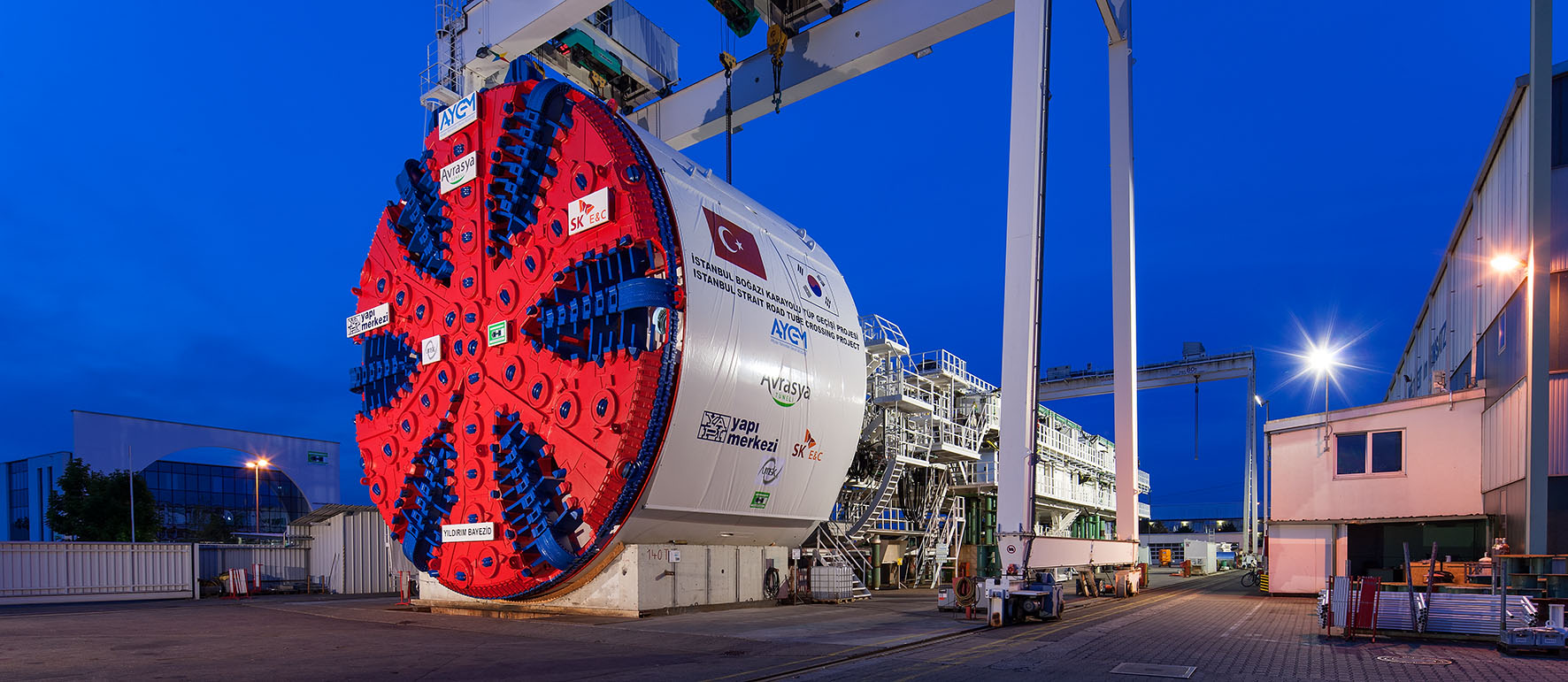

The tunnel is designed for passenger vehicles and small vans with a limited vertical clearance of 2.8m. The Tunnel Boring Machine (TBM) used for this project ranks “first” in the world with its 33.3kW/m2 power per area of cutter head and operating pressure of 12bars for an excavation diameter of 13.7m.

A key challenge overcome during the project was the tunnel location: situated in a seismically active region approximately 17km from the North Anatolian Fault Zone. In order to decrease the stresses and strains forming in the tunnel lining during a seismic event below the permissible levels, two flexible seismic joints were designed specifically for the geological and geotechnical conditions, tested in the laboratory, and implemented as an industry first in TBM tunneling under such high pressure.

The project is considered as a pioneer project not only on account of these technical challenges, but also in respect of its environmental and social policy with the implementation of a comprehensive Environmental and Social Impact Assessment process.

The tunnel opened for operations in December 2016 and will be transferred to the public after 25 years of operation.

Submit your outstanding road project – deadline April 11th, 2018

Established in 2000, the

For more information, please visit

%$Linker: